Gluten-Free Pasta Manufacturing

Market requirement

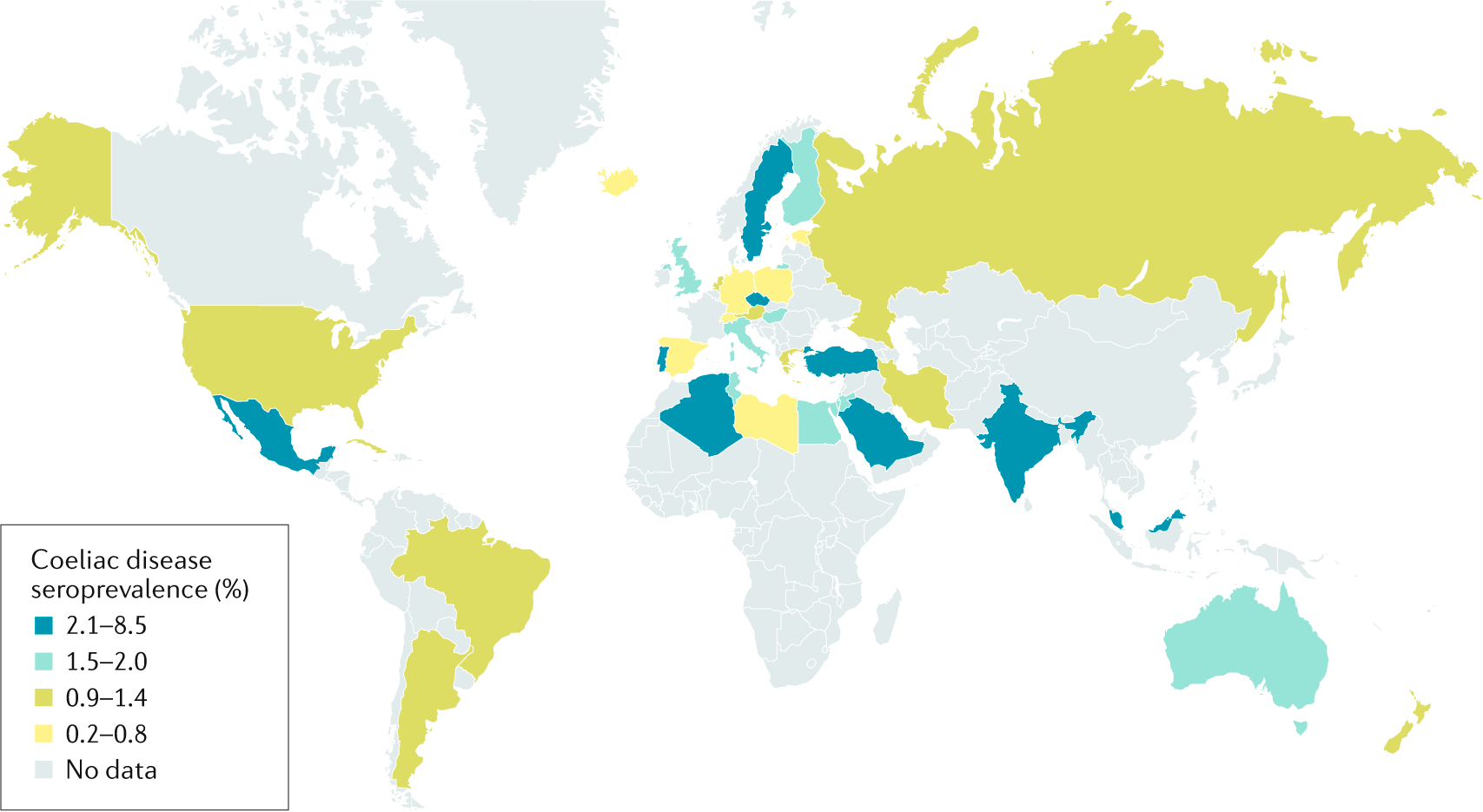

Over the years, the food industry has seen booms, trends, and ‘the next big things’ evolve and change the ways markets work. In the past few years, Gluten-Free has taken over as the way of life for many across the globe. As per an article in Nature, many large economies have >1% of their populations with coeliac disease, an immune disorder caused by gluten-indigestion.

What started 14 years ago as a medical necessity for people with celiac disease or gluten-related sensitivities, the gluten-free diet has now made it into the mainstream. Diet conscious consumer is now mode aware of the health issues and their relation to the food habits. While some stated calling the Gluten-free diet a ‘fad’, there were others who felt better with gluten-free products, which led to high demand for new products like pasta. As per leading marketing analysts, the global gluten-free pasta market is expected to grow with a CAGR of 5.0% between 2021 and 2027. A lot of this new demand will come from developing countries like India.

How Gluten-free Pasta is Made?

Gluten-free pasta is typically made from grains or other ingredients that do not contain gluten, such as rice, corn, quinoa, or legumes (like lentils or chickpeas). To make gluten-free pasta, the grains or other ingredients are ground into flour, and then mixed with water to form a dough. The dough is then cooked, since cooked starch acts as a substitute for gluten-network in providing binding, and then the dough is shaped into the desired pasta shape in the extruder. Like regular dry pasta, gluten-free pasta is dried after it is shaped in order to preserve it and make it easier to store and transport. Drying pasta helps to remove excess moisture from the pasta, which can help to prevent spoilage and extend its shelf life.

It is important for manufacturers of gluten-free pasta to take steps to prevent cross-contamination with gluten during production, as even small amounts of gluten can be harmful for individuals with celiac disease or non-celiac gluten sensitivity. This may involve using separate production lines or equipment for gluten-free pasta, or taking other steps to ensure that the gluten-free pasta is not exposed to gluten during production.

How Zippy can help?

As the demand for Gluten-Free products continues to grow and evolve, Zippy Edibles took a step ahead with India’s First Fully Automated Gluten-Free Pasta Plant in 2020 and created products focusing on delivering greater health attributes. From in-house milling to final packaging, we follow strict International quality standards by being BRC certified, and avoid any chances of cross contamination. European Technology that we use in our plant makes the process of pasta-making seamless and of consistent quality. From making the perfect dough to cooking moulding, cutting and drying, every step in the process is followed to provide a product that customers like.

We have been working with ingredients like ancient grains and pulses to create Gluten-Free products that have healthy attributes, including high-protein and antioxidant-rich. You can relish this fineness and quality in the form pasta manufactured for our own label, Di Grano as well as for select private labels. Go to Gluten-Free Pasta to know more.

To make sure the end product comes with perfection, we have an innovation-friendly Test Plant. This gives us and our clients and economically viable option to experiment and create proprietary formulations. If you’re a distributor or an exporter looking for a reliable contract manufacturer for Gluten-Free products, collaborate with us to innovate, create and grow your business.